EHS Techniques was contracted by a multinational engineering and construction company to estimate fugitive emissions from new units at a chemical plant in Turkey for the production of purified PTA. Reference average emission factors were used after an analysis of the P&IDs. The study included the inventory of each possible source of leakage using an LDAR program management tool.

Project scope

The assessment covered all new process units within the chemical complex, focusing on:

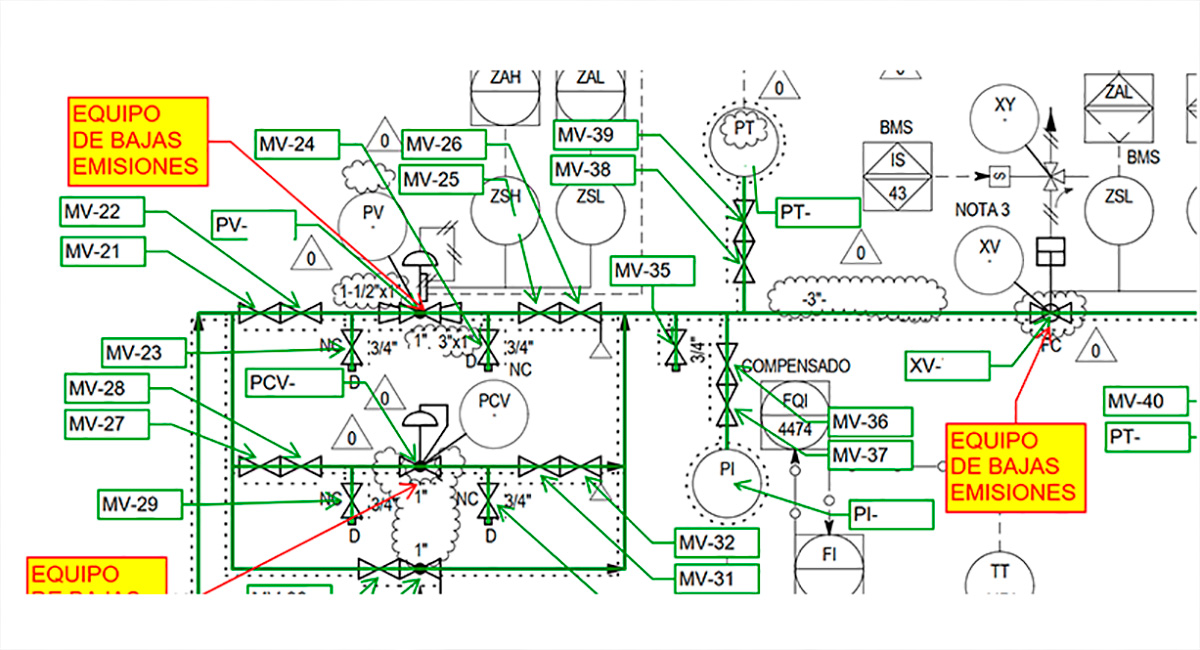

- Identification of potential sources of fugitive emissions (valves, flanges, pumps, compressors, sampling points, etc.).

- Review of Piping and Instrumentation Diagrams (P&IDs) and process flow data.

- Estimation of emissions based on industry-standard emission factors and reference methodologies.

- Inventory and classification of equipment components with potential leakage points.

- Preparation of a detailed LDAR (Leak Detection and Repair) management plan for implementation during operations.

Methodology

The emission estimation process was carried out following internationally recognized protocols and best practices for the Oil & Gas and petrochemical industries:

- Component identification and inventory

- Extraction of component data from detailed engineering documentation.

- Categorization by equipment type and operating conditions.

- Application of emission factors

- Use of average emission factors from authoritative sources (e.g., USEPA, API, EEA).

- Adjustment of factors based on equipment characteristics and service type.

- LDAR integration and emissions modeling

- Incorporation of results into an LDAR management system to facilitate ongoing monitoring.

- Estimation of expected emissions for regulatory reporting and project design optimization.

Results and added value

The study delivered:

- A comprehensive inventory of components susceptible to fugitive emissions.

- Estimated total VOC emissions per process unit, supporting early-stage environmental decision-making.

- A baseline reference for future LDAR campaigns and emissions reduction initiatives.

- Practical recommendations for leak prevention and control measures to be integrated during commissioning.

The results provided the client with clear visibility of potential environmental liabilities and ensured compliance with international environmental performance standards during the EPC phase.

Closing statement

Through this project, EHS Techniques demonstrated its expertise in fugitive emission quantification and LDAR strategy implementation, supporting the Oil & Gas and chemical industries in achieving efficient, compliant, and low-emission operations.

Español

Español